Safety Programs

AMP prioritizes safety with quarterly safety meetings as part of a year-round safety program available to Member employees. AMP’s Occupational Safety and Health Administration (OSHA) Compliance Program is also available on a contractual basis.

General Safety Training

American Municipal Power, Inc. (AMP) Member communities have the opportunity to host an AMP safety coordinator four times per year. AMP safety coordinators offer general training and refresher sessions on safe utility work practices, updates to proposed safety rules and regulations affecting AMP Member communities, and on other topics requested by a community or other issues that may affect AMP Members.

During these crucial visits, AMP safety professionals present on a variety of different subjects. Just a few examples are:

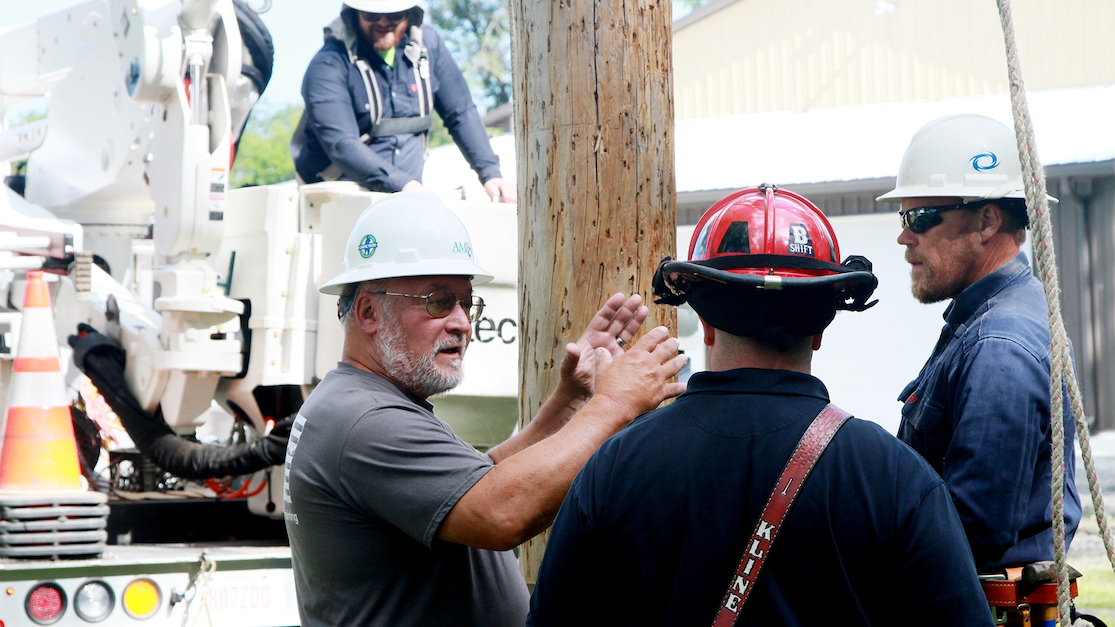

Hurtman Rescue: This topic covers the OSHA-required technique of rescuing a person from a pole or out of an aerial bucket. Every person who climbs a pole or goes up in a bucket truck should be trained annually in this area. This also applies to ground workers. Member communities that have signed the AMP Safety Training contract will be offered the training annually.

Work Zone Safety: This topic covers the proper way to set work zones according to the Federal and State Manuals on Uniform Traffic Control designed to protect the work crews and the motoring public. The presentation covers signage, barricades and other required safety equipment. Additionally, Flagger Certification is offered as a separate course, as many states now require that flaggers be trained and certified in order to flag vehicles on a road construction or utility project.

Accident Investigation/Near Misses: This topic includes the proper steps to take in reviewing and investigating accidents. This presentation highlights the crucial need for reporting both employee injuries and near misses/close calls, even in instances where no injuries occurred. It also shows how to use this information to prevent further accidents and possibly lower Worker’s Compensation rates.

General Safety Review for Lineworkers: This presentation covers daily lineworker safety work practices and techniques. Topics can range from underground residential distribution wire safety, rubber cover-up, personal protective equipment and troubleshooting.

First Responder Electrical Safety: AMP offers a program to instruct first responders on electrical safety and to recognize the hazards in their fields, such as the proper emergency response to electrical incidents at substations, transformers and vehicle accidents.

OSHA Compliance Training

AMP’s Occupational Safety and Health Administration (OSHA) Compliance Program is provided on a contractual basis.

The OSHA Compliance Program is designed to help AMP Members maintain full compliance with all state and federal regulations governing workplace safety for public employees. Compliance with state and federal laws can be a complex task. Many federal and state OSHA standards require employers to develop and maintain written programs and procedures in addition to employee training.

With the OSHA Compliance Program, safety coordinators work with a Member community to tailor the program to the Member’s individual needs. Coordinators routinely establish safety program guidelines; train staff; identify workplace hazards and assist in developing plans to address any hazardous conditions; and plan, organize and conduct monthly safety meetings. The program provides training to all departments and enhances AMP’s general safety program.

All AMP safety coordinators are approved to provide Ohio Environmental Protection Agency contact hours for operator certification renewal for certified wastewater treatment plant, wastewater collections, water treatment plant and water distribution system operators.

Safety Principles

At AMP, we recognize that in order to fulfill our vision of being public power’s trusted leader in providing Members and their customers with the highest quality, forward-looking services and solutions, that an effective environmental, health and safety program is an essential part of who we are and what we do.

By holding true to our Mission, Vision and Values, AMP will:

- Maintain compliance with all environmental, health and safety, legal and regulatory obligations;

- Encourage employees and those working on behalf of AMP to understand and integrate environmental health and safety responsibilities into their business functions;

- Prevent injuries through hazard elimination and employee involvement; and pursue continuous health and safety improvements;

- Encourage and assist AMP Members with their efforts to adopt and follow similar principles.

For more information on any AMP safety programs, please contact Scott McKenzie, Senior Director of Member Training and Safety, at 614.306.4269 or [email protected], or Kyle Weygandt, Director of Member Safety, at 330.323.1269 or [email protected].